The occupational safety action plan is a local document of the organization, which is approved by the employer. It consists of events planned in advance in a certain sequence that need to be implemented in the organization in order to bring labor protection into compliance with legal requirements.

Sample “Occupational Safety and Health Action Plan” List of Occupational Safety and Health Measures (from Order 181n)

How are occupational safety measures regulated?

Occupational safety measures are regulated by Order of the Ministry of Health and Social Development of Russia N 181n “On approval of the Standard List of measures annually implemented by the employer to improve working conditions and safety and reduce levels of occupational risks.”

Order 181n lists all possible labor protection measures, which is why they are called standard. Conventionally, they can be divided into organizational sanitary and technical.

The title says “annually implemented,” although some of them do not need to be carried out anew each time (special assessments of working conditions and training are valid for more than a year).

The sequence of their execution is arranged in accordance with priority. Most often, only a small part of this list is sold. It all depends on the specifics. The more complex and dangerous the industry, the more of this list is necessary for implementation.

Therefore, a specific list of measures to improve working conditions and safety and reduce levels of occupational risks is determined by the employer based on the specifics of its activities.

It is important to note that the planning of occupational safety measures is provided for by standard regulation 438n dated August 19, 2016 for the implementation of the functioning of the occupational safety management system at the enterprise.

How often is a plan made?

Each occupational safety specialist has his own planning frequency. The plans are developed directly by the occupational safety specialist, and approved by the head of the enterprise. If there is a trade union body at the enterprise, plans are coordinated with this body.

We can recommend the following scheme:

- long-term work plan - for a year, approved a month before the start of the planned period;

- current plan - for the quarter, approved 10 days before the start of the quarter;

- schedule for inspection of enterprise divisions - for a month, approved 1 week before the start of the month.

The most important occupational safety measures

Legal measures – provision of documentation, which includes regulations and local documentation on labor protection of the organization. This is the conclusion of individual employee contracts, lists, orders, regulations, etc.

Socio-economic measures - includes compensation to employees for accidents, compulsory insurance, payment of labor benefits to employees with whom the employment contract has been terminated, provision of benefits to employees working in hazardous work, etc.

Organizational and technical measures - creation of an occupational safety and health management system (OSMS).

Sanitary and hygienic measures – ensuring a reduction in the level of exposure to hazardous and harmful factors on enterprise employees, creating favorable working conditions.

Treatment and preventive measures - medical examinations and psychiatric examinations, provision of proper nutrition to workers involved in hazardous work.

Rehabilitation measures – ensuring the speedy restoration of working capacity of an employee who has had an accident or who has received an occupational disease.

Where to start making a plan

Any planning consists of the following stages: Stage 1. Setting goals and objectives. The goal has a general formulation, and the objectives clarify what actions need to be taken to achieve it.

Stage 2. Designation of an action program. Optimal are detailed programs that make the upcoming work as transparent as possible.

Stage 3. Compiling a list of necessary resources to implement the plan.

Stage 4. Determination of performers.

It is recommended to draw up a work plan for an occupational safety specialist based on an analysis of working conditions, the state of occupational injuries and occupational diseases in departments and in the enterprise as a whole. At least 75 percent of working time must be devoted to inspecting production facilities. At the same time, special attention is paid to areas with a high level of industrial injuries and occupational morbidity, with harmful, dangerous and difficult working conditions, as well as high-risk facilities.

The work plan must contain preventive and control measures implemented in the following order:

- removal of dangerous and harmful factors;

- tracking negative impacts at source using engineering controls or organizational measures;

- reducing the influence of production factors to a minimum by designing safe labor systems, including administrative control measures;

- where residual hazardous and harmful production factors cannot be controlled through collective measures, workers are provided with free personal protective equipment, including special clothing and safety footwear;

- organization of preliminary and periodic medical examinations;

- training workers in safe working practices, etc.

How to develop an event plan for the year?

What need to do? First, analyze the expenses of previous years, make a list of all upcoming occupational safety measures, and calculate the cost estimate for these activities. Based on this information, develop and approve a labor safety action plan with management.

Sequencing:

1. Write down all possible activities that may be in your organization from Order 181n “Standard List of Activities”.

2. Ask the accounting department for the costs of the current year’s events in order to more accurately predict the events for the next year

3. Ask the HR department for a list of current employees and plans for hiring new ones in order to predict activities for them (training, briefings, medical examinations, etc.).

4. Talk to department heads. Find out what changes have taken place in the field of labor protection (workwear has worn out, pro-free allowances have increased, etc.). Find out what your plans are for next year (purchase of new equipment, adding new employees, etc.).

5. Familiarize yourself with the documents in which labor safety measures are implemented : professional assessments, special assessment cards, regulations of supervisory authorities, etc.

6. Make a final list of activities in order of importance. First, indicate the mandatory ones - training, preliminary and periodic medical examinations, special assessments, then the optional ones - purchasing a stand, new collective protective equipment, etc.

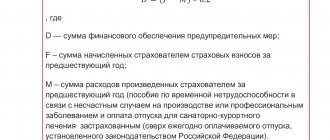

7. Make an estimate of labor protection costs:

- All organizations, with the exception of government ones, are required to spend at least 0.2 percent of the cost of producing their products on labor protection measures. (Article 226 of the Labor Code of the Russian Federation). Therefore, ask the accounting department for the costs of production for the last year.

- Ask your planning department or accounting department about budget planning to find out how the budget is planned in your organization as a whole.

- Assess the cost of material assets that will have to be purchased, as well as the cost of services from third-party organizations in the field of labor protection. You should know how much personal protective equipment, fire extinguishers, safety devices, worker training, special assessments, etc. cost.

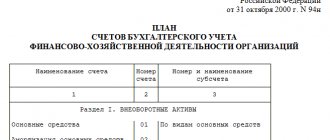

8. Develop and approve with management a plan of occupational safety measures based on the list of activities and cost estimates. According to standard provision 438n on OSMS, the plan should include:

- results of working conditions;

- list of events;

- responsible persons;

- the timing of each event and what results are expected.

It is necessary that the action plan be recorded on paper and approved by the employer. However, there is no approved form as such, so it is formed in free form. The main thing is that it is understandable and meets current needs. It may contain both the name of the event and the calculation of the financial component. It all depends on how work is organized within the organization.

The fine for the absence of a labor safety action plan ranges from 30 to 90 thousand, or suspension of the company’s activities for up to 90 days. (Article 5.27 of the Administrative Code)

Main conclusions

Drawing up an action plan to improve working conditions is an important task, even if you do not apply to the Social Insurance Fund for reimbursement of labor protection expenses.

If you have been working as an occupational safety specialist in an organization for several years, then drawing up an action plan for the year will not be difficult; you know all the “sore spots” that need to be “treated.”

And if you have just started fulfilling your duties, then Order of the Ministry of Social Health Development No. 181n will be of great help to you; it contains all the main points that are suitable for both large companies and small businesses, which also could use occupational safety planning.

And if there is a point in carrying out activities, and there is one - creating safe working conditions, then there comes a moment when the amount of work performed turns into a quality result, the absence of fines and harm to the health of workers.

I wish you safe and efficient work!

If you have any questions after reading the note or you have something to add, give examples of effective application of the plan, write in the comments, it will be useful to other readers!

Example of a simplified occupational safety and health action plan for an accounting firm

When developing an occupational safety and health action plan, many factors must be taken into account. Let's start from the very beginning of the office. The organization has just registered. He rents an office and begins moving into it and recruiting staff.

The action plan might look like this:

1. Fire safety measures:

— preparation of an evacuation plan; — purchase of fire extinguishers; — maintaining related documentation; — purchasing signs and “Exit” signs in case of fire evacuation; — development of a fire safety training program; — appointment of those responsible for the premises.

According to the law, the owner is always responsible for the premises, but very often the landlord shifts part of the responsibility to the leasing organizations. The above is a list of the most common events that rental organizations face. Therefore, when choosing a room, you need to take this point into account.

If the owner of the premises is the employer himself, then care must be taken to ensure that the premises meet fire safety requirements (presence of warning systems, serviceability of fire hoses, unhindered access to emergency exits, and so on).

2. Organization of a preliminary medical examination for hired employees (if necessary), as well as psychiatric examinations and pre-departure medical examination (if necessary).

From May 24, 2022, such examinations were canceled for office employees, however, if the company has a driver, then such examinations are necessary for him (psychiatric and pre-trip). The same applies to other non-office specialties, if they are included in the organization’s staffing table.

3. Conducting a special assessment of working conditions.

— determination of the list of workplaces subject to SOUT; — concluding an agreement with a certified organization; — assistance to the organization in the process of conducting a special assessment; — submission of reports on the results of the implementation; — familiarization of employees with the results; — organization of events recommended based on the results of the special assessment.

Carrying out this event will allow us to determine working conditions. Including the materials of the special assessment of working conditions, based on its results, there will be a list of recommended measures that you can add to the plan for the next year (for example, replacing lamps with brighter ones, etc.). However, if everything is in order at the workplace, then there will be no activities in the SOUT materials.

4. Organization of the necessary training on labor protection for managers and employees of the organization (HSE, HSE, civil defense and emergency situations) in accordance with the internal structure of the organization.

In this case, you send for training the general director, heads of structural divisions and other responsible persons who will directly monitor compliance with labor protection requirements and, thanks to the training, will have the opportunity to conduct briefings.

5. Creation of local regulations and documents:

— OT management system; — orders appointing those responsible for various issues related to labor protection; — training programs; — labor protection instructions; — accounting journals; - other related documentation (here you can describe in detail what kind of documentation (that is, related to medical examinations, psychiatric examinations, operation of a company car, and so on).

Documentation is maintained depending on the specifics of the organization’s activities. The more complex and dangerous the industry, the more paperwork will need to be maintained. The list of documents is created based on the legislative act under which you are working.

6. Creation of jobs that meet labor protection requirements:

— the presence of grounding on all equipment used in work; — use only serviceable and certified equipment; — lighting sufficient to perform work duties; — purchasing or making warning signs (“Caution wet floor”, “Caution step”, etc. This will be individual in each case); — purchase of comfortable ergonomic furniture.

You should not skimp on your employees. A comfortable and safe workplace, where the employee will not have back, eye pain, etc., will do his job better.

7. Organization of work and rest schedule and comfortable working conditions:

— approval of the work schedule and regulated breaks; — organizing a place for storing and eating food (if the premises allow it, since eating is prohibited at work places); — availability of ventilation, heating and air conditioning systems to maintain optimal microclimate parameters; — purchase of coolers with drinking water and conclusion of an agreement with the organization for a constant supply of water; — purchase of household appliances for the dining room; — organization of a smoking area in accordance with fire safety requirements.

Creating conditions for comfortable rest will allow your employees to recover faster and thereby increase their ability to work.

8. Purchase of stands, visual materials, scientific and technical literature for conducting briefings.

This event will allow employees to focus their attention on important issues related to their safety.

9. Instructing employees in safety rules:

— carrying out all necessary briefings; — testing knowledge of labor protection requirements; — internship on labor protection in the workplace; — maintaining documentation related to these activities.

The quality of this event determines how seriously employees will take the announced rules. If the event is held “formally for show,” then the attitude towards it will be appropriate. The task of an occupational safety specialist is to increase the self-discipline of employees in matters of compliance with safety requirements.

10. Monitoring compliance with workers’ labor rights

In accordance with the labor code. This includes compliance with the work and rest schedule, timely payment of labor, including payment for overtime and work on weekends and holidays. In some cases, the employer’s compliance with requirements related to the health of employees (short shifts, medical leave, work restrictions due to pregnancy, etc.)

11. Organization of compliance by employees with labor protection requirements and internal rules of the organization:

— taking action against employees who violate safety requirements; — carrying out measures aimed at preventing the recurrence of such situations.

12. Organization of investigations of workplace accidents in the event of employees being injured while performing their work duties.

This is roughly what the list looks like for 1 year of operation of a new organization. In the future, this list will only contain control over compliance with all activities and the timing of their implementation. This is necessary in order to organize repeated briefings, training, SOUT and other events that are periodic.

Thus, a labor protection specialist, based on information obtained in the course of his work, organizes labor protection and safety measures. It is worth noting that almost all of the activities listed in this article imply the correct management of document flow, one way or another related to the event being implemented.

Development of a labor safety action plan is one of the most important stages. Such a plan is usually drawn up for a year. In it, the specialist describes the organizational and technical measures for labor protection in order of their importance, thus setting priorities. At the same time, he sets tasks and distributes responsibility in order to be able to control the progress of the planned activities.

After the period for which the action plan was developed, the success of its implementation is summed up. A comparative analysis is carried out (pre-event/post-event) and a new plan is developed. Thus, each subsequent one increasingly improves the level of labor protection in the organization. Ultimately, all that remains is control over the frequency and maintenance of the functioning of labor protection.

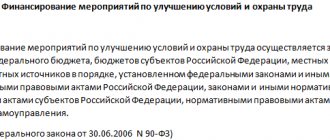

How to make a plan to improve working conditions

To create this plan, you can’t just sit down and write it on a piece of paper. The whole process will have to be divided into several stages:

- The head of the organization issues an order appointing a responsible working group and a person regulating the direction of its work.

- The group itself is created from employees of the enterprise.

- The group develops a draft action plan, the project is approved by management.

- An estimate is being developed in accordance with the approved plan.

To develop the plan, the group analyzes similar events in past years. If the plan is being drawn up for the first time, you can use the work of your colleagues and look for forms on the Internet. But it is better, of course, to turn to professionals who will take into account the specific features of your enterprise.

Attek company has been in the technology market for more than 20 years. We will not only prepare an action plan for you that complies with current legislation, but we will also train your staff. Yes, an integral part of ensuring safe work is regular testing of safety knowledge and training of your own specialists. In our training center you can train all categories of your employees in one place, including using remote technologies.

When drawing up an estimate according to the plan, it is necessary to take into account a number of important factors:

- The need for SOUT.

- The need to modernize equipment.

- Types of activities of the organization.

- The presence or absence of regulations from regulatory organizations (for example, GIT).

Who is on the working group to develop the plan?

The working group includes the management of the enterprise at all levels. There are three levels of system management:

- senior level - manager and his deputies, chief engineer, chief specialists;

- secondary - heads of structural units, mechanics and technologists;

- junior - foremen, foremen, foremen.

People are selected from among the managers of each unit to form a working group. The composition of the working group is approved by the leader by order.

Monitoring the implementation of the action plan

To check the implementation of the plan, a commission is created from the manager and persons appointed responsible for labor protection. The audit is carried out twice a year. Based on the results, an inspection report is issued, which indicates the identified violations and an action plan to eliminate them.

At the end of the agreement, the responsible persons submit a report on the activities carried out.

Agreement with the occupational safety and health action plan may be required by the labor inspectorate during the inspection. Therefore, the employer needs to take care of drawing up the document in advance and thereby insure its employees against accidents and professional accidents. diseases, and themselves - from a fine for violating the requirements of labor protection legislation.

How to identify the right directions

In addition to the measures mentioned in Order of the Ministry of Health and Social Development No. 181n, management has to implement other measures. But how to determine what a specific organization needs at a specific time. This will help:

- SOUT results. An independent examination gives an objective idea of what needs to be changed;

- proposals for improving working conditions coming from the team. If employees ask you to install air conditioning or insulate wires, you should listen to them;

- personal observations. A competent leader will certainly notice what is missing in the territory entrusted to him for greater comfort;

- methodological recommendations for improving working conditions, developed for a specific area. They can be created by industry associations or specialized researchers.

Drinking expenses

The costs of purchasing coolers and drinking water also haunt the capital's employers. According to clause 2.19 of the Resolution of the Ministry of Labor of the Russian Federation of February 27, 1995. No. 11 “On approval of Recommendations for planning occupational safety measures”, occupational safety measures include the acquisition of equipment for supplying drinking and carbonated water, tea and other tonic drinks to workplaces. This means that in justifying the purchase of coolers or drinking water, you can refer to this resolution.

In addition, the Office of the Federal Tax Service of Russia for the city of Moscow at the beginning of this year presented a letter dated January 30, 2009 No. 19-12/007411. In it, the tax authorities explained that the costs of purchasing water may be considered unreasonable if the rent includes payments for cold water supply. However, there is an exception to this case, if the organization, as confirmation of the legality of including these costs in expenses, submits a certificate from the sanitary and epidemiological station stating that the water provided for paid use by the lessor is not suitable for use by employees, then such expenses can be taken into account.

Please note that drinking water must comply with the “Sanitary and Epidemiological Rules and Standards “Drinking Water. Hygienic requirements for water quality of centralized drinking water supply systems. Quality control. SanPiN 2.1.4.1074-01" (approved by Resolution of the Chief State Sanitary Inspector of the Russian Federation dated September 26, 2001 No. 24).

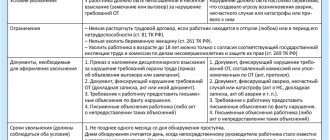

Security measures

The Labor Code contains a significant list of labor protection measures that must be carried out. In this article, we will consider only those for which the attribution of costs to expenses causes the greatest number of disputes between taxpayers and inspection staff. So, the main ones are:

- acquisition and issuance at our own expense of special clothing, special shoes and other personal protective equipment, flushing and neutralizing agents that have undergone mandatory certification or declaration of conformity in the manner established by the legislation of the Russian Federation on technical regulation, in accordance with established standards to employees engaged in work with harmful and (or) dangerous working conditions, as well as work performed in special temperature conditions or associated with pollution;

— sanitary, medical and preventive services for workers in accordance with labor protection requirements, as well as delivery of workers who fall ill at the workplace to a medical organization in case of need to provide them with emergency medical care;

— compulsory social insurance of workers against accidents at work and occupational diseases;

— familiarization of workers with labor protection requirements, etc.

The legislation establishes a list of works that are included in the concept of “sanitary and household” services, namely: equipment of sanitary facilities, premises for eating, premises for providing medical care, rooms for rest during working hours and psychological relief; creation of sanitary posts with first aid kits stocked with a set of medicines and preparations for first aid; installation of apparatus (devices) to provide workers in hot shops and areas with carbonated salt water and more.

Medical and preventive services are the production at the expense of the employer or his vehicles of transportation to medical organizations or to the place of residence of employees who have suffered from industrial accidents and occupational diseases, as well as for other medical reasons.

In addition to all of the above, Law No. 52 of March 30, 1999 - Federal Law “On the Sanitary and Epidemiological Welfare of the Population” (you can find the full versions of these documents in the Consultant Plus legal reference system) establishes the obligation to comply with sanitary rules by citizens, individual entrepreneurs and legal entities . So, failure to comply with the rules may result in prosecution, and, according to Article 55 of the above-mentioned law, even criminal liability.

At the same time, the rules are established by law for each type separately; among the main ones we can highlight “Hygienic requirements for the microclimate of industrial premises. Sanitary rules and regulations. SanPiN 2.2.4.548-96" (approved by the Resolution of the State Committee for Sanitary and Epidemiological Supervision of the Russian Federation dated October 1, 1996 N 21), "Sanitary and epidemiological rules and standards "Hygienic requirements for the organization of work on copying equipment. SanPiN 2.2.2.1332-03" (approved by the Chief State Sanitary Doctor of the Russian Federation on May 28, 2003), "Sanitary and Epidemiological Rules and Standards "Hygienic requirements for personal electronic computers and work organization. SanPiN 2.2.2/2.4.1340-03" (approved by the Chief State Sanitary Doctor of the Russian Federation on May 30, 2003), "Sanitary rules and regulations "Hygienic requirements for insolation and sun protection of premises of residential and public buildings and territories. SanPiN 2.2.1/2.1.1.1076-01" (approved by the Chief State Sanitary Doctor of the Russian Federation on October 19, 2001), as well as building codes and regulations SNiP 2.09.04-87 "Administrative and domestic buildings" (approved by the Resolution of the State Construction Committee of the USSR dated December 30, 1987 No. 313).

We protect workers' labor

According to the norms of the Labor Code, the employer’s responsibilities include ensuring normal working conditions for its employees.

These include, in particular: — good condition of premises, structures, machines, technological equipment and equipment;

— timely provision of technical and other documentation necessary for work;

— proper quality of materials, tools, other means and items necessary to perform the work, their timely provision to the employee;

— working conditions that meet labor protection and production safety requirements.

Maintaining the premises and work items of employees in good condition is, among other things, also beneficial for the employer himself. After all, it’s unlikely that anyone will want to deal with sick leave, where the reason for absence will include a work-related injury. And the labor inspectorate will be only too happy to check your company’s compliance with labor laws and fine you for violating it.

In addition, providing for the everyday needs of employees related to the performance of their labor duties is, according to the Labor Code of the Russian Federation, another responsibility of the employer.

Accordingly, labor protection is one of the mandatory areas for any entrepreneur. It is a system for preserving the life and health of workers in the process of work, which includes legal, socio-economic, organizational and technical, sanitary and hygienic, treatment and preventive, rehabilitation and other measures. Moreover, safe working conditions are those in which the impact on workers of harmful and (or) hazardous production factors is excluded or the levels of their impact do not exceed established standards.

Federal laws and other regulations establish state regulatory requirements for labor protection. They are mandatory for legal entities and individuals when carrying out any type of activity. These rules must also be observed during the design, construction (reconstruction) and operation of facilities, the design of machines, mechanisms and other equipment, the development of technological processes, the organization of production and labor.

At the same time, it is worth noting that the responsibility for ensuring safe conditions and labor protection rests directly with the employer.