FREE CONSULTATION WITH A LAWYER

Tel.

+7 (800) 302-65-54 Free in Russia

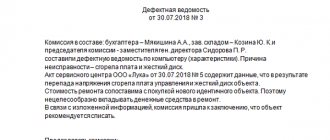

In the event of a breakdown, defect, or non-compliance of the condition of mechanisms, engineering systems, or their individual elements with accepted regulatory standards, a so-called defective statement must be drawn up, the form and sample of which are given below.

Blank defective statement form (word)

Sample defective statement (word)

Example of a defective statement form for write-off (word)

Purpose of the document

In general, a document such as a defect sheet does not have a single approved sample, therefore defect inspection forms (as it is also called) are always developed independently. As a rule, the organization initially approves certain uniform forms, which are subsequently applied in different cases.

The document always reflects the following points:

- Name of the object that has technical defects.

- A complete list and detailed technical description of the defects found.

- Repair methods for each or a group.

The order of compilation can be:

- planned - in large companies, this or that equipment is always periodically checked to ensure that it is in full working order;

- unscheduled - in case of special inspections, after accidents, etc.

Thus, a defective statement is the main reporting document that describes any deviations of a product, mechanism or engineering system from the state accepted by the standard:

- external defects;

- internal faults;

- defects made by the manufacturer;

- mechanical damage caused during transportation and/or operation of equipment, etc.

This statement can be compiled by representatives of any interested party - both companies and individuals:

- manufacturer;

- buyer;

- seller.

General rules for their compilation

Despite the fact that there is no approved sample of a defective statement, this document refers to the primary accounting documents, therefore, in relation to it, the general rules for preparing accounting reports should be taken into account:

- The following mandatory details must always be present in the troubleshooting:

- the actual name;

- Date of preparation;

- the full official name of the institution or company where the defect was drawn up (for example, the name of the manufacturer or company that sells the equipment);

- name, essence and measurements of the conducted business transaction in kind and monetary equivalent;

- persons who carried out the detection of defects - their full names, positions and signatures.

- The right to sign such a document is not granted to all employees, but only to those who belong to the list approved by the manager together with the chief accountant of the enterprise.

- It is drawn up either at the moment of detection of defects, or immediately after the completion of the procedure - depending on technical feasibility.

- Corrections, blots, and typos in the defective statement are not allowed - if there are any, you must draw up a new document on a new form.

- Compilation in both traditional paper and electronic form is allowed.

- Only authorized persons (usually the chief accountant and the head of the company), as well as representatives of inspection and control authorities - the tax inspectorate, the prosecutor's office, etc., can make a claim.

Rules for drawing up a defective statement

At the moment, there is no single unified form of the document in question, which must be used by companies in practice. A sample of the defective statement must be kept in each department. It is understood that companies must independently develop a statement template that will include the following necessary information :

- Business name;

- number and date of formation of the statement;

- all parameters characteristic of the damaged object.

The specified parameters, in particular, include the name of the object, which must correspond to the entry on the balance sheet of the enterprise, detected defects with a note about the cause of the breakdown. Indicating the cause of damage is the responsibility of the entity servicing the facility. The statement must also reflect how the problem was resolved, which is the responsibility of the repair department employee. It is recommended to format object parameters in table form.

If necessary, the statement must include links to third-party materials, for example, photos of the breakdown, basic details of the defect report, etc.

Inaccuracies noted in the defective statement can be corrected by crossing them out and marking the correct data above. Such correction must be endorsed by the signature of the responsible entity with the date of the correction. However, if possible, it is strongly recommended to create a new document without errors.

So, the paper in question can be drawn up on a standard A4 sheet or on letterhead. It also does not matter whether the document is drawn up by hand or on a computer. It is appropriate to prepare the statement in several copies, depending on the number of interested parties. All original documents must be endorsed by all members of the commission, as well as the manager.

In this case, the defective statement may not contain a seal, since this requirement was abolished back in 2016. However, if businesses use a stamp in their daily activities, this must also be affixed.

After the statement expires, it must be transferred to the company’s archive, where it will be stored in accordance with the law or local regulations.

Step-by-step instructions for creating a defect sheet:

- In the upper left or right corner, general information about the director of the company is indicated in several lines. It should be noted his position, full name, as well as the name of the company.

- In the middle of the sheet is written the name of the paper being generated, its registration number is indicated in accordance with the internal document flow, and the city where the statement was compiled is also recorded.

- Then comes the main body of the document. It is in this block that information about the damaged object should be disclosed. It is recommended to create a table. In the first column, as a rule, the serial number is entered, in the second - the identified defects, in the third - ways to eliminate them, and in the fourth - the deadlines for when the problems must be eliminated are specified.

- Finally, the defective statement (each of its original copies) must be signed by all participants in the procedure.

Filling out the defect sheet

According to the instructive technical and accounting documents, the defect list is the creativity of the managers of each company and company individually. But, despite this, there is a certain set of requirements for filling out this important primary document.

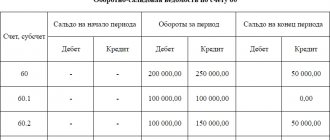

First of all , this is solely required by the purpose of the statement. It is a reasoned basis for attributing financial costs for repairs to accounting accounts.

Basic filling requirements

This is standard information, as shown in the sample, that is necessarily contained in the document for this purpose.

Both the statement and the act require the following items:

- The standard name of this document.

- Date of compilation of the statement.

- The nomenclature name of the organization whose employees compiled the documents.

- Business transaction with full name.

- List of meters for necessary business transactions in physical and monetary terms.

- A register of positions of employees who are responsible for carrying out a business operation, the accuracy of its implementation and registration.

- Signatures of the commission members.

Drawing up a defect sheet

Defective documents require certain adherence to the compilation and execution algorithm. First of all, primary documents of this order require urgent completion, which is due to certain features that lie in the legal field.

That is, it is extremely important to prepare statements during the period of the commission examination. If there are certain objective circumstances and it is impossible to complete the statements, then it is necessary to bring the registration to its logical conclusion immediately after the completion of the inspection of the object.

Recommendations when drawing up a document

When preparing these accounting acts, you must follow the following recommendations:

- Fill quality.

- Timely transfer to the accounting department.

- Accuracy and reliability of data.

- Corrections must be signed by responsible persons.

- Today, specialized websites offer unified forms that can be easily downloaded and used in the company’s future activities.

An example of filling out a defective statement (filling out a defective statement)

Above we described how a defective statement is compiled in accordance with the Law “On Accounting”. At the same time, each organization determines the set of necessary attributes independently, and the above list of information can be significantly reduced (if the defective statement is not compiled for accounting and tax accounting purposes, when the primary document must meet clear requirements) or expanded.

As you can see, the defective statement for the repair of premises in terms of the description of the business transaction should reflect such parameters as:

- description of detected defects and damage;

- list of repair and restoration work;

- volume of detected defects;

- deadlines for eliminating identified defects;

- cost of repair and restoration work.

If, for example, a technical mechanism is inspected, the commission evaluates the condition of its individual parts, on the basis of which it makes a conclusion about the need for repair/restoration work or the write-off of part or all of such a mechanism.

Samples of different types of defective statements 2022

There are several types of defect detection, each of which has its own characteristics:

- To renovate the premises (or the entire building).

- For roof repairs.

- For vehicle repairs (truck, passenger car, special purpose).

- For heating system repairs.

- For writing off spare parts.

In general, the sample contains the following points:

- The “I Approve” visa is entered in the “header” with the signature of the director or other authorized employee, on whose orders the inspection is being carried out. The same person is approved by the commission and the corresponding order is signed. The official name of the company is also written here.

- Next, write the name of the document and its number - usually in simple chronological order, for example, “Defective statement No. 77.” The date of inspection is also entered here.

- Then write the full name of the technical object or engineering system that was inspected.

- The descriptive part, which is the basis, is presented in the form of a table. Here, in order (indicating the number), all external defects, mechanical damage, and malfunctions that were discovered during a simple visual inspection of the object are listed. Specific types of work aimed at eliminating these faults are also prescribed, as well as a deadline for completing the repairs.

- Finally, the names and positions of the employees who carried out the inspection are written down, and their signatures are affixed.

The document is drawn up during the inspection of any product, device, even office equipment. Thus, the sample defective statement does not depend on the object of inspection - it is approved as an empty form that is used by all employees in their work.

Vehicle repair sheet

If a company uses a company car or if it owns a whole fleet of vehicles, the quality of the cars is periodically monitored by external inspection.

It is compiled both by the company that owns the vehicle and by the repair company where restoration work is expected to be carried out.

Drawing up a document in this case allows you to solve several problems at once:

- report to the tax office on the expenditure of certain funds on minor or major repairs of the car;

- record all defects and, based on their analysis, determine the effectiveness of investments in the repair and maintenance of the vehicle (total costs and total income for the foreseeable period);

- Finally, with the help of this document you can clarify the specific type of repair work that will be needed in this case, as well as their estimated cost.

When drawing up a defect report for the repair of a machine of any class and purpose, attention should be paid to several important features:

- The name of the model or specific technical modification of the car must completely coincide with what is indicated in the documents - in particular, abbreviations, letter case (uppercase or lowercase), spaces or continuous spelling.

- The names of spare parts and individual units should be written with the same accuracy - usually they can be clarified in the relevant documentation or on the manufacturer’s website.

- In such a statement, references to applications are required - i.e. documents regulating the implementation of repair work, the purchase of certain spare parts, etc.

- Signatures are required not only from the responsible persons who conducted the survey, but also from the owner of the car, if the car does not belong to the company itself, but to an employee who entered into an appropriate agreement and provided his car for official use.

- Since the inspection and repair of a car is a rather complex technical procedure that requires the preparation of extremely specific records, corrections even with the mark “corrected believe” are not allowed.

- Finally, the number of copies of such a defect is determined by the number of interested parties, of which in this case there are quite a lot: this is the company itself that uses the car, its owner, the company carrying out the repairs. However, if the company repairs its own machine on its own, the defective statement is drawn up on 1 form.

An example is presented below.

For room renovation

During a scheduled inspection, the entire building or its specific premises are inspected, and, as a rule, several fault inspections are made - each for its own premises, or all the data is combined into one document, if it is more convenient to process the information.

The main purpose in this case comes down to the following:

- describe all external defects, violations of the condition of the building (for example, cracks in the ceiling, ruptures in the floor covering, mold in the corners, etc.);

- outline ways to eliminate it – i.e. specific types of repair work with the help of which it is expected to cope with all detected deficiencies;

- indicate the timing of the work, and since we are talking about fairly large volumes, it is necessary to determine priorities - for example, first of all, repair of doorways, and secondly, elimination of cracks in ceilings.

Such a statement is usually compiled by 2-3 employees, among whom are:

- accountant or chief accountant;

- repair specialist;

- engineer in charge of equipment in a building.

The defective statement form must include the following information:

- All information relating to the building as a physical object - what address it is located at, what is located in it.

- The shortcomings themselves are in their exact names.

- Methods and timing of work to correct detected deficiencies.

Since a building is a fairly large object, and a variety of deficiencies can be found, when drawing up a defect report and actually planning the work, you should pay attention to a number of features:

- The repair work itself is named in strict accordance with the accepted naming system - here you need to refer to the relevant reference literature (Federal and territorial unit prices).

- When recording and describing the type of repair work, you should indicate not only the period, but also the volume, and at each stage you need to identify a specific responsible person - as a rule, there will be several of them at once.

- All equipment, as well as construction and other materials intended for repairs, are registered in the names as they are indicated in the documentation - i.e. Brands and models are written in full, without abbreviations.

A sample of the defective statement is presented below.

For heating system repairs

When conducting scheduled and unscheduled monitoring of the heating system in a building, the commission usually consists of 2 people:

- accounting representative;

- heating system repair specialist.

Several design considerations should be taken into account:

- Compiled before or during renovation. If it is quite difficult to do this, then the deadline for drawing up is immediately after completion of the work.

- As a rule, not only the names of repair operations are written down, but also the units of volume, as well as the responsible persons at each stage (if the work is supposed to be carried out in several stages).

- Corrections in the text itself are also not allowed in this case.

- As a rule, it is compiled in electronic form, but there should always be a paper counterpart.

A sample of such a defective statement is given below.

NOTE. The repair work itself – i.e. routine repairs or in the event of an accident do not imply drawing up a defect report according to the appropriate sample.

For write-off of spare parts

The write-off of spare parts is understood as a business operation to replace old, worn-out mechanisms of any installation with new parts. In this case, in the case of car spare parts, it is assumed that a corresponding defective list will be drawn up, a sample of which is discussed above.

Features of the compilation are as follows:

- All equipment that was inspected is written down in simple lists.

- It will be correct and convenient if, along with the description of the objects, the inventory numbers of each of them are also indicated.

- You should also pay attention to the fact that the name of each spare part is indicated in exact accordance with how it is given in the technical documentation.

- The “conclusion” column indicates that the part is considered unusable, obsolete and needs to be replaced (or written off).

A sample is presented below.

For roof repairs

Along with the defect detection, the form of which is drawn up during the inspection of the building, a separate document is developed that describes the shortcomings of the roof and the corresponding repair work. A sample is provided below.

What is a defective statement

In life, people often have to deal with various breakdowns, flaws, defects or outright defects discovered in the process of acquiring or using material assets. To correct the identified deficiencies, it is necessary to carry out a certain set of measures related to restoration (repair) work. For these purposes, a special document is drawn up, which is called a “defective statement”. It allows you to calculate and take into account in advance the costs that will need to be spent on repairs in order to return material assets to their original appearance and characteristics.

In production conditions, such events are carried out purposefully. A preliminary commission is appointed by a separate order, which will subsequently assess the scope of repair work. It must include representatives from:

- accounting;

- equipment operation divisions;

- adjustment and repair services.

A defective statement is drawn up after a visual inspection. It should contain information that will answer three main questions:

1) Name of the object being examined. This applies to a greater extent to the accountant, since it is he who has complete information about all objects on the balance sheet of a given enterprise.

2) Identifying faults and determining the causes of their occurrence. Here the equipment maintenance specialist should have his say.

3) List all types of work that need to be performed to restore the functionality of the object (node). This information will be provided by the repair site employee.

Based on the information received, a defect sheet is generated. This document does not have a strictly regulated model. Each individual enterprise independently develops such a form and approves it by a separate order. The finished document must be signed by all members of the commission and approved either by the head of the enterprise or an authorized person from the administration in charge of this object. Subsequently, the defect sheet is used to draw up estimates for repair and restoration work.

Why do you need a defective statement?

Before answering the question of how to draw up a defective statement, let’s consider its purpose. A defective statement is a document that reflects flaws, defects, defects, deficiencies in equipment, consumables, goods, results of production activities and other material assets (hereinafter referred to as MC). It can also be used when accepting work or goods by a consumer who has discovered certain shortcomings in them.

All this is necessary:

- to justify the reasons for writing off certain MCs;

- justification for the organization's expenses related to the repair, restoration or replacement of the MC specified in such a statement (including for tax purposes);

- accounting purposes at the enterprise;

- general accounting of MC at the enterprise after inventory (see article Sample act of inventory of inventory items>);

- planning the financial, economic and investment policy of the enterprise (for example, for drawing up estimates for repairs, purchasing equipment, etc.), etc.

In addition, a defective statement, compiled and executed properly, can be used in court as material evidence. In itself, such a statement cannot always serve as evidence; often, in addition to it, other documents are also required (including an inspection report, an estimate of restoration work, acceptance certificates for work performed, etc.).

What is the difference between a defective statement and a defective act?

In most cases, the act approves the statement in the form of an appendix. An act (protocol), unlike a statement, is drawn up by its own employees appointed by the manager and for this reason is most convenient for an internal turnover document. Together, the documents are considered the commission’s report on the inspection of the building.

Procedure for documenting defects

In the case of companies with a small staff, there is often no particular need to develop, prescribe and approve a procedure for checking equipment and drawing up a defective list, since such situations arise quite rarely.

However, in the case of large companies, equipment quality monitoring is carried out only according to pre-drafted and approved regulations. In general, the order is as follows:

- The management of the company or a specific branch issues an appropriate order to conduct a scheduled or unscheduled inspection.

- This order reflects the authorized persons who will be part of the inspection commission: at least 2 employees . It usually includes not only representatives of technical services (engineers, technicians, quality controllers), but also accounting departments.

- Direct quality control is carried out, a defective statement is drawn up on a pre-prepared form, signatures are placed, after which the document is handed over to authorized persons.

NOTE. The verification procedure using a defective list should not be confused with technical expertise. Planned quality control is, as a rule, only a visual inspection of external surfaces, mechanisms, and connections of parts. At the same time, examination involves a more in-depth analysis of the mechanism using special equipment for testing.

Bill of quantities and defective list - what's the difference?

Often, when drawing up a list of defects for any type of construction, you may also encounter such a phenomenon as a bill of quantities. In fact, the defective statement is also a statement of quantities. Then it seems logical to ask how a defective statement differs from a bill of quantities.

The fact is that the construction of any facility may require not only work to identify or eliminate defects, but also additional work or work, without which the successful commissioning of the facility is impossible. For these types of work, a separate local estimate or resource estimate must also be drawn up, and subsequently reports of completed work will be drawn up in the KS-2 form, as well as a sample accumulative sheet in construction. For example, when compiling a statement of quantities for excavation work, the document may include additional work on development or backfilling of soil, transportation of excavated soil, loading work and many other types of work that for some reason were not included in the original project and estimate documentation. Thus, it turns out that the concept of a statement of quantities is broader than the concept of a defective statement.

Based on all of the above, we can conclude that the defective statement is a complex document in construction, which is drawn up with the participation of many representatives. And the total estimated cost of construction of the entire facility will depend on how accurately and correctly the defective statement is drawn up.