Basic rules for drawing up a commissioning act

When choosing a form for drawing up an act, there is no need to adhere to strict rules. There is no single form for these purposes. The act is allowed to be drawn up in free form on a blank A4 sheet. Although practice shows, many companies develop a special template for this.

Regardless of which filling option was chosen, it is necessary to remember some rules for preparing such documents. Information about the company that received the equipment and is going to operate it must be specified here. You also need to indicate the conditions under which the equipment will be used and technical data about it. You need to remember the main rule - the more complex the device, the more points should be made in the act.

It would be useful to point out that the new equipment meets not only the current legislation, but also the internal requirements of the company. If the commission has identified shortcomings, all comments must also be indicated in the document. If a defect is detected, a defect report is drawn up. Naturally, until all problems are resolved, using the device is strictly prohibited.

What equipment needs to be put into operation?

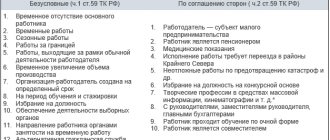

As already mentioned, any equipment entering the organization’s balance sheet is subject to inspection. Moreover, it does not matter whether it was a purchase, rental, or another reason for the receipt of a complex device. However, this is not the only reason why a thorough check is carried out.

There are situations when a company’s equipment has not been used for a long time. Naturally, after such downtime, you need to check whether the device meets the necessary standards. As a rule, equipment is subject to inspection if it has been idle for more than one year. It doesn’t matter whether it is simply not used as unnecessary, or is undergoing long-term repairs, the device must be checked.

How to draw up an act correctly

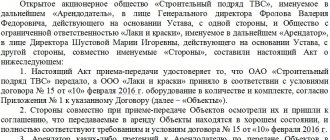

As a rule, the act is drawn up between two parties: the transferor of the fixed asset and the recipient of it, incl. putting into operation.

Representatives of the parties in most cases are directors of companies, their deputies or heads of structural divisions.

However, if necessary, a third party can be involved in the form of experts (this is especially true in cases of transfer of complex technical equipment, instruments, machinery, and various types of structures).

The act refers to primary documentation, therefore, since 2013, the requirement to draw it up according to a strict unified template has been abolished. Today, enterprises and organizations have every right to compose it in any form or according to a template developed and approved within the company.

An important condition: in its structure and content, the act must comply with certain standards of office work, business documentation and the rules of the Russian language.

The document must include some mandatory information:

- a link to the agreement, to which the act is an annex, as well as the number, date, place of its creation;

- enter information about the enterprises that form the act;

- indicate the name of the fixed asset, the address at which it is installed or put into operation;

- describe the tests and inspections to which the fixed asset was subjected, as well as their results;

- the conclusions should record the suitability of the fixed asset for further use and the date from which it can begin to be used in work.

If there are any additional accompanying papers, they must be noted in the act as a separate item.

Stages of equipment commissioning

The equipment commissioning procedure can be divided into several main stages:

- Creation of a commission. The head of the organization appoints specialists who will inspect the unit. In addition, representatives of the company that acts as a supplier may also be present. If this is a new device, the selling company often sends an employee to be present even during unpacking.

- Direct inspection. In the process of checking equipment, it is often necessary to disassemble it. Accordingly, the commission should include specialists who can do this correctly. It is also checked whether the technical condition corresponds to the information specified in the documents.

- After inspection, specialists conduct tests. For example, a test run is done to determine how well the equipment operates.

- Based on the results of the inspection, a report is filled out. The members of the commission are listed here and the equipment is described. It would be useful to indicate exactly what testing work was performed and what devices were used for this. At the end, the review team must draw a conclusion. If there are faults, they are indicated. In addition, experts give recommendations on how to eliminate them. If a defect is detected, a defect report is drawn up and sent to the supplier. If there are no comments, it is indicated that the equipment can be put into operation.

There are situations when an organization does not provide for drawing up an act upon commissioning. Moreover, this can apply to absolutely any equipment. In general, the law allows you to do without this document. It can be replaced by an act of acceptance and transfer, which indicates the date when exactly the use of the device began. However, practice shows that almost all organizations still draw up this document.

After all, this is the only way to be sure that you have received fully functional equipment, and in case of any problems you can count on help from the supplier. In fact, the act of commissioning can be called a kind of guarantee, and not only for the recipient. The supplier also needs the document. After all, this is how he will know that the equipment was actually defective and did not break during use.

Instructions for filling out the equipment commissioning certificate

Filling out the document can be divided into several parts:

- First, the “header” is indicated, which should contain the title of the document and its essence. The filling date and city must also be present here.

- Below is the composition of the commission that inspects the equipment. Here you need to indicate not only the names of the specialists, but also their positions. Also in this paragraph it is necessary to note information about the manager and information about the order by which the representative of the inspection team was appointed.

- Next comes the main part, which describes the fact of inspecting the equipment. Here it is indicated what kind of equipment we are talking about, its number, technical condition, manufacturer and other parameters are written down. The period during which the inspection was carried out is also indicated.

- Below is a list of results. Moreover, each action must be described on a new line. Information is provided here that the equipment meets the required standards. Information about the test run is written down. Any additional information is provided.

- The conclusions are stated below. If there are no comments, the commission indicates that it gives permission for commissioning.

- A list of documents that are annexed to the act is indicated.

- Original signatures of all members of the inspection team and the director of the organization.

You also need to understand that the technical condition of the equipment is not always satisfactory. There are situations when the commission identifies certain problems that do not allow the equipment to be fully and safely operated. Accordingly, the commission does not have the right to issue a permit. In this case, information about the breakdown is entered into the report. If there are several of them, each of them should be described in detail. In addition, experts draw conclusions that indicate recommended work aimed at troubleshooting. After repairs are completed, the equipment must be re-inspected.

Repairs are often necessary when equipment has been idle for a long time. But there are situations when faults are detected in a newly purchased device. In such situations, the report is sent to the supplier, who must deal with the problem.

Basic provisions

The introduction of equipment into production must be confirmed by written evidence. Hence the definition of the concept.

The equipment commissioning certificate is an official document that records the technical condition of the devices and the degree of their compliance with the regulatory and technical standards of the enterprise. Inspection and testing are needed in different situations. For example, if the equipment is only “from the factory”, used, repaired or even modernized. If it is not checked, operational problems may arise.

Formatted in the form:

- Additions to the main agreement or contract (for example, purchase and sale or leasing of equipment);

- An independent document.

Before drawing up a report, the commission must ensure that the equipment is inspected as completely as possible. All devices are checked for defects and malfunctions. They are launched to test the functionality and methods of proper operation. Tests allow you to assess compliance with technical, fire and environmental safety standards.

If the inspection reveals malfunctions in the equipment or its non-compliance with standards, a remark is made in the text of the Commissioning Certificate. Immediately and in parallel, a defect report is filled out - about the identified deficiencies and the time frame for their elimination. Only after restoration work and re-commissioning activities will it be possible to sign the equipment commissioning certificate.

Sample of filling out the equipment commissioning certificate

What additional documents are needed for permission?

Quite often, various documents are attached to the act. For example, these could be supply contracts, a purchase and sale agreement, a protocol for commissioning and installation work. It all depends on the specific situation and the complexity of the equipment being inspected. For example, almost every complex device must be accompanied by rules of use and a technical data sheet. Also, repair certificates, commission conclusions, and technical acts are often used as attachments.

After all members of the inspection team sign the report, it, along with all available additional documentation, is transferred to the accounting department. This is where the process of placing equipment on the balance sheet of the organization takes place.

Don’t forget that if the document is properly drawn up, the full picture of the device is visible. Of course, this is important for the supplier. But this information is also necessary for the organization itself. Thus, the director and staff specialists will know the capabilities of the equipment received and the rules for its use. This also allows you to correctly calculate depreciation. Thanks to the commission's conclusion, staff will know what maintenance the equipment needs. Of course, this helps prevent breakdowns and ensure long-term and efficient operation.