By law, all organizations must provide their employees with special clothing, as it is necessary to protect them from unwanted environmental influences while performing their duties.

Accounting for workwear in 1C 8.3 Accounting 3.0 is carried out in accordance with Order of the Ministry of Labor No. 997n. In this step-by-step instructions, we will look in detail at the entire process of writing off workwear in 1C with different useful lives due to the fact that accounting standards for them differ.

Purchasing workwear

First of all, you must reflect in the program the purchase of the workwear itself. To do this, go to the “Purchases” section and create a new document “Receipts (acts, invoices)”.

Fill out the header of the document, indicating the standard details of the supplier, your organization and where the purchased goods will be listed.

Our team provides consulting, configuration and implementation services for 1C. You can contact us by phone +7 499 350 29 00 . Services and prices can be seen at the link. We will be happy to help you!

In our case, the organization purchases rubber boots, a blue cotton robe and cotton gloves. As you can see, in the figure above, all item items have an accounting account of 10.10. 1C 8.3 filled it out automatically.

If this does not happen for you, go to the card of the corresponding item item and make sure that “Workwear” is set as the item type.

We will also check the rules for determining the accounting accounts for the rubber boots we buy. Her priority score is 10.10.

We will not fill out anything else in this document. Now you can carry it out and check the correctness of the formation of movements.

How to choose work gloves

- Types of work gloves

- Materials

- Coating

- Men's sizes

- Women's

- size table

- Construction gloves

Work gloves are one of the personal protective equipment that prevents hand injuries during various types of production activities. To select them, it is important to know the hazardous production factors in a particular area, the duration of work, hand size, the presence of allergic reactions in the employee and other conditions.

Types of work gloves

The main function of work gloves is to protect hands from various damaging factors. Therefore, when choosing, first of all, you need to take into account the specifics of the activity and safety requirements. According to the level of protection, gloves can be divided into three types: for minimal, medium and irreversible risks.

Gloves are also divided into two categories according to areas of use - universal and special. The former are used during any activity that requires minimal protection of hands from punctures, cuts, dirt, dust and water. Such models are usually used for simple and non-hazardous work or at home. These can be thin latex or low-knit knitwear with PVC coating.

Special gloves are necessary only for certain jobs, as they have specific characteristics - high resistance to acids, flame resistance, and increased puncture protection. They are more reliable, safer and more durable than universal ones, but cannot be used for different types of work at the same time.

Materials

The material for gloves is selected according to several parameters: in addition to protective properties, wear resistance, elasticity, ergonomics, and breathability. In some cases, certain qualities have to be sacrificed for the sake of safety: for example, when working with aggressive chemicals, acid resistance is more important than breathability. The most popular materials for sewing gloves are cotton, split leather and latex.

Cotton is the basis of knitted gloves. This is a safe, hypoallergenic, highly breathable material. These gloves do not restrict movement, preserve sensitivity of the fingers, and fit comfortably on the hand. They get dirty easily, but are also easy to wash. They can be reused after washing.

Cotton gloves are universal. By themselves, they do not have increased protective properties, but in many activities this is not required. Builders, loaders, gardeners, cleaners, food and clothing industry workers use knitted gloves.

Cotton is used as a basis for the production of specialized protective gloves. The fabric can be given additional properties by impregnation or spraying with other materials: latex, polyvinyl chloride, nitrile. To give cotton gloves elasticity, synthetic thread is included in the yarn composition. Wool is used in knitted gloves to protect against cold.

Split leather is the bottom layer that remains after tanning genuine leather. This is a dense and durable material that is difficult to cut or puncture. But the main property of split leather is resistance to high temperatures. It does not deteriorate from hot sparks, does not ignite in fire and protects your hands from burns. Split high gloves - gauntlets - are worn by welders, metallurgists, turners, and oil workers.

Latex is a water-based dispersion of rubber, which is also used to make rubber. Latex products protect against water, dirt, dust, acids, alkalis and other chemical and biological substances. The material is quite elastic and durable, but does not have reliable protection against punctures and severe mechanical damage. Latex has one significant drawback - increased allergenicity. Latex gloves are worn by workers in the chemical industry and medicine.

Important! Latex can be replaced by other artificial materials - vinyl, nylon, neoprene, nitrile. Vinyl is cheaper and easier to produce. Thin nylon fits well on the hand and does not reduce the sensitivity of the fingers, which is important in high-precision production. Nitrile is more puncture resistant and is particularly resistant to paints, varnishes and acids. Neoprene is ergonomic, it stretches well and does not interfere with long hours of work.

When producing work gloves, materials can be combined. For example, the outer layer is made of latex, and underneath there is a layer of PVC to protect against allergic reactions. Sometimes inserts from other materials are used: Kevlar, fur, leather, rubber.

Coating

For increased strength, adhesion to the surface, and protection from aggressive substances, special coatings are applied to cotton gloves. The most common materials for additional layers are PVC, nitrile, regular or foam latex. Polyvinyl chloride protects against injuries and prevents slipping, nitrile creates oil and petrol resistant protection, latex improves moisture resistance, wear resistance and protection against chemicals.

The coating of work gloves can be continuous, incomplete, dotted or double. A spot coating of PVC is applied to the material using a stencil. The pattern can be anything: dots, waves, Christmas trees, bricks, stripes. More material is applied to the ends of the fingers, since these places require increased grip. This coating slightly improves wear resistance and reduces slipping, without compromising the breathability of the product.

Partial coverage is applied to the palm only. This part of the hand is more likely to be injured than the back. In addition, this method of pouring gloves allows you to improve the anti-slip properties without sacrificing wearing comfort. Gloves with incomplete coverage on the palm are used by builders, installers, and loaders. They are suitable for working with glass, metal, heavy or fragile objects.

Full coverage is necessary for reliable protection against chemicals during prolonged or close contact with alkalis, acids or oils. Such gloves are more resistant to mechanical damage and wear out more slowly. But they are also not as comfortable, soft, or sensitive as products with less coverage. For increased comfort, the full coverage is sometimes made corrugated, but the protective properties in this case are reduced.

Double pouring can be continuous or non-continuous. Two layers of material increase wear resistance and protective properties, but also increase the weight and density of the glove.

Dimensions

Work gloves should fit well. Too large ones can fall off the hand, reducing protection, grip and sensitivity of the fingers. Tight gloves are uncomfortable and wear out faster.

Gloves that are incorrectly sized reduce productivity and increase injuries.

Important! The size of gloves is determined by the girth and length of the palm of the leading hand. To measure the girth, you need to wrap a meter tape approximately in the middle of your palm, just above your thumb. Do not press your thumb against your palm; the measurement is carried out without it. Palm length is measured from the beginning of the hand to the tip of the middle finger.

4.1. Men's

The same size chart is used for men's and women's models. Most of the products from the manufacturers of this personal protective equipment are universal, intended for both men and women. In fact, such gloves usually fit better on a man's hand than on a woman's. Therefore, both men's and universal gloves are suitable for male workers.

4.2. Women's

A woman's hand differs from a man's not only in size. She has different proportions: a smaller width of the palm at a certain length and a smaller width of the fingers. Therefore, it is more convenient for women to wear special women's glove models that take these features into account.

4.3. size table

When choosing a size after taking measurements, you need to check a special table designed for work gloves. Standard sizes in the European classification are 6, 7, 8, 9, 10 and 11. Each corresponds to certain values for the volume and length of the brush. If your hand has non-standard dimensions - too wide or narrow, it is better to focus on volume rather than length in the table, so you are more likely to choose the appropriate size.

| Glove size | Palm circumference, mm | Brush length, mm |

| 6 (S) | 152 | 160 |

| 7 (M) | 178 | 171 |

| 8 (L) | 203 | 182 |

| 9 (XL) | 229 | 192 |

| 10 (XXL) | 254 | 204 |

| 11 (XXL) | 279 | 215 |

Choose size

Protection classes

Work gloves protect against the following factors:

- From mechanical influences. They are resistant to punctures, cuts, tears and abrasion. These gloves are used by loaders, builders, and miners.

- From high temperatures - open fire, hot surfaces, sparks, metal splashes, heat. They are required by metallurgists or welders.

- From chemistry. Such gloves do not allow acids, solvents, oil, paints, hazardous biological substances, and solvents to pass through. They are suitable for work in laboratories, chemical production, medicine, and the oil industry.

- From low temperatures. These are insulated gloves for working outdoors in winter or when in contact with cold surfaces.

- From electric shock – dielectric. Gloves that do not conduct current are needed when working with electrical appliances.

Each type includes several categories, and each category includes several classes. For example, gloves against mechanical damage may have protection against abrasion, breakthrough, blades, and puncture. Abrasion protection has four classes, and blade protection has 5 classes. In this case, the grades indicate how many work cycles it took during testing to tear, puncture or cut through the product.

Chemical protection classes depend on the time it takes for a hazardous substance to penetrate the material: class 1 gloves can withstand 10 minutes of acid or alkali, and class 6 gloves can withstand 480 minutes. When determining fire protection classes, the time during which the material smolders is taken as a basis.

The type and protection class of work gloves is determined by the markings on the product. For example, EN 388 4X32 means that the gloves protect against mechanical damage, have abrasion class 4, cut resistance is not tested, tear resistance is class 3 and puncture resistance is class 2.

Production of work gloves

Work gloves are produced on manual or electronic machines. Electronic equipment allows for more careful control of the process, which improves product quality. Gloves made in modern factories with electronic machines last longer on average.

The quality of work gloves also depends on the availability of specialized equipment. For example, in many factories, when producing knitted gloves, one type of machine is used: it knits the product itself and at the end makes an automatic overlock. If the overlocker is stitched using separate special equipment, it will more reliably protect the cuff from yarn unraveling.

The power and quality of the equipment is of great importance. In the production of knitted gloves, the most expensive machines are those that apply PVC coating to the material, so some manufacturers save on them. But products made on low-quality or insufficiently powerful machines have a short service life: for example, PVC dots begin to fall off even before use.

Areas of application

Work gloves are used in any enterprise: from the chemical industry, where hand protection from acids and alkalis is required, to electronics production, where assembly requires high sensitivity of the fingers, precision of movements, complete absence of lint and microparticles. Builders, medical workers, gardeners, mechanics, welders, auto mechanics, and loaders protect their hands with gloves.

7.1. Construction gloves

At a construction site, work gloves are needed for any work, from installing structures to plastering. Construction gloves must protect against mechanical damage - abrasion, cuts, punctures. Wearing comfort is also important, as construction workers have to spend many hours on end wearing gloves.

These requirements are met by knitted gloves with dotted PVC coating. They are elastic, do not restrict movement, and protect against minor injuries.

7.2. Repair gloves

Work gloves are needed for finishing, plumbing, and electrical work during renovations. The requirements for functionality are no different from construction ones - they must protect against mechanical damage, dust and dirt, ensure hand grip on work surfaces and be breathable.

For dry, long-term work during repairs, universal cotton gloves with PVC coating are suitable. When interacting with water, chemicals, large amounts of dirt and dust, you need to choose latex, nitrile or nylon products.

7.3. Gardening gloves

It is also advisable for gardeners to have several pairs of gloves for different activities. For most gardening work, it is important to protect your hands from dirt, minor scratches and punctures. Cotton gloves with spot PVC coating are suitable for this.

When watering and working with fertilizers, protection from water and non-aggressive chemicals is needed. Latex or nitrile gloves can handle this. When weeding, planting small plants or sorting vegetables and fruits, your hands should remain sensitive and free to move, so it is most convenient to wear thin, finely knitted items without covering. And when pruning bushes or working with thorny plants, you need protection from punctures; in such cases, split-leaf gloves are used.

7.4. Gloves for working with glass

To work with glass, you need products with increased anti-slip properties and protection against cuts. Good contact with the glass surface is ensured by nitrile, polyurethane or latex foam. Latex-coated Kevlar products best protect against cuts from sharp glass edges and glass fragments. Thin Kevlar has a high level of sensitivity, which is also important for working with glass. But uncoated Kevlar products are not suitable, as they can slide on glass - you need to choose models with latex or another coating.

7.5. Welding gloves

Welding gloves are called gauntlets because they have a special design. They are distinguished by wide, elongated cuffs that reliably protect hands and wrists from sparks, metal drops and fire. The length of the product can be different: from the middle of the forearm to the elbows.

Welding gaiters are most often made from split wood. This material is resistant to molten metal, high temperatures and fire. It is characterized by wear resistance, cut resistance, breathability and low price.

There are welding gaiters made of genuine leather. They differ from split leather by better tactile properties, they are more convenient to work in, but they are also more expensive.

Interesting! Crags come in one-toed, three-toed, and five-toed varieties. Single-fingered gloves are suitable for simple welding work. If greater precision of movements is required, you need to choose three-fingered or five-fingered models.

7.6. Gloves for the food industry

Gloves for working with food must first of all be hygienic, hypoallergenic, safe and easy to clean. It is important that the material is non-porous, does not absorb water and does not leave microparticles. The ideal choice is nitrile: it is convenient when working with edible fats, protects against cuts and abrasions, does not reduce sensitivity, is easy to clean and does not cause allergies like latex.

A good replacement for nitrile gloves is vinyl: affordable, hypoallergenic and reliable. Food processing plants also widely use disposable polyethylene gloves, which guarantee sterility when in contact with food products. When working with sharp knives, you need stainless steel chainmail gloves designed to protect your hands from deep cuts.

7.7. Gloves for medical workers

Medical gloves must provide a reliable barrier to biological or chemical substances. They are subject to high requirements for cleanliness, since the hands of doctors must be sterile.

Traditionally, disposable latex products are used in medicine. Latex models provide maximum sensitivity and freedom of hands. But they are allergenic, which is why there are medical gloves made of nitrile, neoprene and vinyl.

Buy work gloves Select gloves

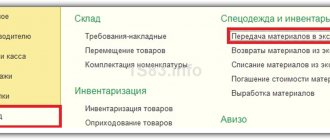

Transfer into operation

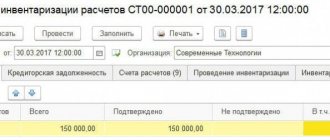

After the fact of receipt of workwear was reflected in 1C 8.3, it began to be listed in the main warehouse as account 10.10. Now you can issue it directly to the organization’s employees. The document “Transfer of materials for operation” is used for this purpose. You can create it based on the workwear receipt we just created.

1C Accounting automatically filled in all possible fields, but suppose that we want to put into operation only 10 rubber boots. In the tabular part we indicate physical. person - Abramov Gennady Sergeevich. It is he who will now be credited with rubber boots.

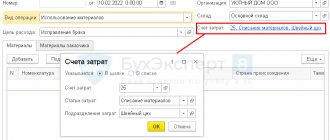

Pay special attention to filling out the “Purpose of Use” column, which is marked in the image above. It contains an element of a special directory, which indicates the procedure for repaying the cost of special clothing and special equipment.

You can fill out this guide yourself. In our example, the linear method of paying off the cost was chosen. We are going to reflect expenses on account 25.

Assume that the useful life of the rubber boots in this example assignment will be 11 months. In accordance with the law, such workwear can be written off immediately if the period does not exceed 12 months.

After entering all the data, the document can be processed.

Document preparation

Workwear is written off for various reasons: as a result of wear and tear, accidents, employee dismissal, etc. Based on the results of the inspection, a document is drawn up and signed in two copies by members of the inventory commission operating at the enterprise. Indication of the composition of the commission, as well as the person who approves such paper, is mandatory. We remind you that financially responsible persons are not included in the inventory commissions, but are required to be present during their work.

- Name and nomenclature number of the special equipment.

- Unit of measurement.

- Quantity to be disposed of.

- Unit cost.

- Date of start of operation.

- Established service life.

- Recommended write-off date.

- Reason for departure.

The absence of any of these points may cause the document to be declared invalid and casts doubt on the operations carried out on its basis. The organization has the right to indicate additional information about material assets at its discretion and accounting specifics. The disposal list is summarized in numerical and capital form.

It is important to carefully consider the reason for disposal of clothing. The expiration of the period of use established by the enterprise is not a reason for disposal. If the special clothing is suitable for further use, it could be issued to the employee again. The reason for disposal may be loss or wear and tear.

Discarded clothing is destroyed in the presence of the commission, or is taken to the enterprise warehouse as rags for further use. This information must be reflected in the act. It is also necessary to note the amount of damage recovered from the financially responsible person for the loss of material assets.

Disposal of workwear

Based on the transfer of materials into operation, this workwear can be written off.

The document was filled out automatically, and all we had to do was change the number of rubber boots to be written off.

After posting the document in the postings, you can verify that all boots in the amount of 10 pieces were written off from the account MTs.02.

Physical deterioration

Write-off of workwear that has become unusable ahead of schedule occurs if this is confirmed by acts of the inventory commission. Only in this case will the CO be written off before the due date. It is also required to prove that physical wear and tear was not the fault of the employee. In cases where most sets of special protective clothing become unusable ahead of schedule, the standards for issuing CO at the enterprise or the quality of the clothing issued should be reviewed.

It should be noted that the standards for issuing special protective clothing are established by current legislation, but the employer can change the established limits:

- reduce the period of use of special clothing (it is impossible to increase this period beyond the established norm);

- replace workwear with another type (based on written agreement with the labor safety inspectorate);

- issue special clothing to employees for whom this clothing is not provided (by agreement with the trade union).

It is also impossible to reduce the write-off rate for special clothing. If an employee is entitled to 2 sets of underwear per year, the employer cannot reduce this norm to one set. In case of such violations, the enterprise is subject to an administrative fine, and in case of repeated violations - suspension of activities for up to three months.

It follows from the above that the employer can increase employee protection and increase the standards for issuing protective equipment, but not vice versa.

Return from service

Sometimes in practice there are cases when workwear needs to be returned from use. There can be many reasons for this phenomenon, for example, dismissal, sick leave, business trip or transfer of an employee.

A document for the return of their use can be created based on the transfer of materials into operation.

In this case, just like in the previous example, you just need to indicate the quantity. The image below shows an example of the return of one pair of wellington boots.

After posting the document, we see that one pair worth 150 rubles has been written off from account MTs.02. The boots accounting account has changed from 10.11.1 (in service) to 10.10 (in warehouse).

Application

As the name implies, household gloves are used to perform “household work” - washing dishes, cleaning an apartment, office or other room. When cleaning the toilet and bathtub. When carrying out painting or repair work, during which hands may become heavily soiled with paint, varnish, putty or other similar substances.

Household gloves are also used when working with soil at the dacha, when planting plants in the ground, weeding the garden, and when caring for indoor plants.

For work related to water, gloves made of both natural and artificial rubber are well suited.

Another area of application for household gloves is food preparation. When washing vegetables and fruits, when processing meat, mushrooms and fish, the use of gloves will protect you from possible damage and contamination. This is especially true for women who take care of their hands and, in particular, their nails.

Rubber household gloves should not be used to protect hands from exposure to technical oils, solvents and gasoline, as they are not oil- and gasoline-resistant.

Repayment of cost

We will add one more item to the previously introduced transfer of workwear - “Blue cotton robe” in the amount of 5 pieces. In the purpose of using the robe, we indicate that its useful life will be 18 months, that is, a year and a half.

Repayment of the cost of the robe will be made at the close of the month. In our example, all documents were posted from September 2022. In this regard, the operation we need to pay off the cost of the robe will be carried out at the close of October 2017. A similar scheme is used for depreciation of fixed assets.

Let's consider the transactions created by the operation of repaying the cost of workwear and special equipment in October 2022. As shown in the figure below, a write-off was made for the robe in the amount of 97.22 rubles. This amount will be used to repay the value of this position within 18 months.

In accordance with the specified data in the intended use, the calculation turned out as follows:

- 5 (number of bathrobes) * 350 (price of one bathrobe) / 18 (useful life) = 97.22 rubles.

Accounting and tax accounting of workwear

The term “working clothes” is used in relation to the individual protection of company employees. This category includes both clothing and safety shoes and other devices that perform a protective function.

Regulatory acts regulating the issue:

- Tax code;

- Order of the Ministry of Finance No. 135n;

- Certificate on the standards for issuing protective clothing and other protective equipment to employees free of charge;

- Labor Code in articles 221 and 209;

- Order of the Ministry of Labor No. 997n;

- Code of Administrative Offences.

Current legal documents provide for fines for non-compliance with the rules for issuing protective clothing. For officials, sanctions are provided in the amount of 20,000 - 30,000 rubles, and for companies themselves in the amount of 130,000 - 150,000 rubles, calculated on a per-employee basis.

Representatives of certain types of professions (for example, builders) and employees of a number of enterprises receive protective clothing in accordance with current legislative standards. The regulations regulate both the terms of use of items and the amount of uniform workers receive. The issuance procedure is determined by current industry regulations or existing model rules. The basic requirement is the free provision of protective clothing. At the same time, the items continue to remain the property of the company and are listed on the balance sheet of the enterprise, which bears the costs of cleaning and washing. Certification of clothing is mandatory.

The basic document regulating the issue was the order of the Ministry of Finance numbered 135n. Within the framework of this regulatory act, accounting for workwear should have been carried out similarly to working capital. To do this, it was necessary to open two subaccounts for materials in the warehouse (10.10) and for those used by employees (10.11).

Then the regulations changed and today it is allowed to use PBU 6/01, which applies to “Accounting for fixed assets”. It is important to consider that we are talking about workwear used for more than a year. In addition, the cost criteria must correspond to the requirements of fixed assets.

For a detailed consideration of the rules for registration and write-off, we will focus on the standards used in the “traditional” approach. We are talking about adding special clothing to the 10th account. Understanding the cost of items and planned terms of use allows you to correctly write off. Thus, you can choose from several options:

- When operating for less than a year, expenses in accounting are included in expenses when transferred to employees;

- When used for more than a year, accounting is carried out using linear write-off methods over the time of use of the clothing.

Tax accounting rules provide that the cost of workwear is immediately included in expenses, in accordance with Article 254 in paragraph 1. Thus, when calculating income tax, a temporary difference arises.

It is important to understand that the taxpayer retains the right not to immediately write off the cost in tax accounting. Expenses can also be reflected in several reporting periods. When maintaining accounting records, it is also possible to write off the cost of workwear not immediately. Such postings are possible when items have been used for less than a year. In this case, the linear method is applied and costs are incurred over the entire period of use. But the chosen procedure is necessarily fixed in the accounting policy.

Certificate for writing off gloves x b sample

» October 24, 2022

__________________ ____________ 201_. The commission consisting of ___________________________, _______________________________, (position, full name) appointed by order for LLC _____________ dated _______________ 201_ N ___________, wrote off the following materials due to their unsuitability for further use: Persons due to the fault of which the studied materials turned out to be unsuitable for use, the following were recognized: ________________________________________________ Yes for Olga wrote: Bronsi wrote: Olga wrote: Hello, maybe of course it’s off topic, how can you make standards for writing off materials that are issued to the cleaner , soap, cloudberries and all that?

It's your right to develop standards. Do it in any form (as is convenient for you). Only then will you have to do an analysis (I do it at the end of the year), and everything that is above the norm will have to be written off at the expense of profit. So, if everything is bought differently every month, should we make new norms every month or what?

We recommend reading: Vacation schedule, order classification

and what does it mean to do analysis? For what? Cleaning agent (powder) - 3 pcs (for example, you will have some kind of Pemolux or something else), do not indicate the name of the product, Cleaning agent (gel) - 2 pcs (for example, Sanfor, Sanox, etc. ) Washing powder - 3 kg Toilet soap - 5 pcs Materials represent a material reserve purchased by an organization for the production or maintenance of a certain process.

All of them are recorded on established accounts. If a defect or damage is detected, they are written off.